The nautical world is pivoting toward sustainability – using renewable bio materials, lowering vessel weight, adapting to new fuels and new drives. A new possible future is taking shape, one in which our stance toward cruising, yachts and oceans differs radically from our current practices

‘Navigare necesse est, vivere non est necesse’ – timeless wisdom of Roman statesman Gnaeus Pompeius say it all. Navigation, no matter the circumstances, is essential to humanity, connecting coasts and people, pushing us further into exploration and fostering global economy. Those of us who consider boats and yachts something to be mostly enjoyed in leisure time don’t have to navigate no matter the circumstances – so what if our little nautical fun is irreparably damaging the environment, ruining the future of our children and wasting the little fossil fuel the planet has left?

Maximized efficiency results in lower fuel consumption, and ultimately, to the possibility of achieving higher speed with weaker engines. This is primarily achieved by lowering vessel weight, which today is mostly the task of advanced design programs, capable of finding ways to lower the weight without impacting negatively vessel robustness.

Modern building materials, like carbon fiber or Kevlar are often used for production of parts that need to be super robust, and at the same time super light – seeing how on single-hull vessels roughly 60 feet in length every additional tonne of weight translates into 1 knot less of speed.

This strategy is rather popular at the moment, and for example, this September, Ferretti Group have announced investment into a dedicated carbon fiber plant. In addition to using lighter materials, boat builders have focused on energy conservation and material frugality during the very building process – French builder Beneteau have designed an efficient emission-lowering strategy based on using more bio-ingredients for production of their polyester resin, and using recyclable resin, to lower carbon footprint of the hull building process up to 70 percent in comparison to building in currently used standard plastic materials.

Recyclable or recycled materials and fabrics have also found their way into yacht interior design. Produced, made and finished in sustainable way, they are every bit as luxurious and stylish as their previous-generation counterparts, so it is little wonder recycled marble, recycled cellulose or plastic have become a mainstay on many a modern yacht, an excellent example of that being the extremely popular and omnipresent artificial teak decking.

In addition to lowering overall weight and using non-traditional materials, another important method of lowering the carbon footprint of a vessel is using smart hull design. Two great examples of smart hull design are Azimut Magellano 60, which you could have read about in our previous issue, and Greenline 58, presented in this issue.

The two share smart hull design, as well as energy efficient engines. Since they have pivoted to bio-diesel fuel, Azimut have also started a carbon footprint certification initiative, similar to the automotive industry practice. Magellano 60 is powered by bio-diesel engines using fuel from sustainable sources, and Greenline 58 is a hybrid model, powered by both diesel and electric engines, using batteries charged by generators or diesel engines themselves. Greenline is one of several builders focusing on hybrid models, and popularity of those models through the years demonstrates the potential of such technology. Other successful examples of hybrid engines include Volvo Penta Aquamatic, used for Arctic tourism and handling extreme conditions mere 800 km from the North Pole.

Meanwhile, Nimbus 395, which we tested for this issue, uses electric engines only. Builder Axopar have earlier this year purchased electric engine maker Evoy, and the largest electric-powered double hull in the world, Sunreef Eco 80, is a popular guest of all relevant yacht shows.

Electric engines will probably be the first and already are the simplest type of alternative marine engines, and are expected to gain even more popularity in the next few years, as electricity supply grid is easy to create and maintain.

Still, seeing how current technology does not allow electric vessels the range that is easily attained by vessels with traditional engines, hybrid engines are currently more popular. Pure electric engines are still limited to small-range vessels. One of the solutions, currently popular among builders, is addition of foils, which allow the vessel to elevate itself above the surface and become a hydrofoil vessels less sensitive to drag.

Two builders who have successfully coupled foils and electric engines are Candela and Tyde; Candela with their recently launched passenger ship, and Tyde with model Icon, presented in our previous issue. Electric engines and foils allow easier power transfer from engines to the propulsion system, as electric engines can be installed onto the very foiling fins without long and complex shafts, and can easily be integrated with a single ship computer system.

In addition to electric and hybrid engines, already present in the market and gaining popularity, many new technologies and types of fuel are being developed for marine use, be it for work ships or leisure boats.

Find our more about this futuristic watercrafts here.

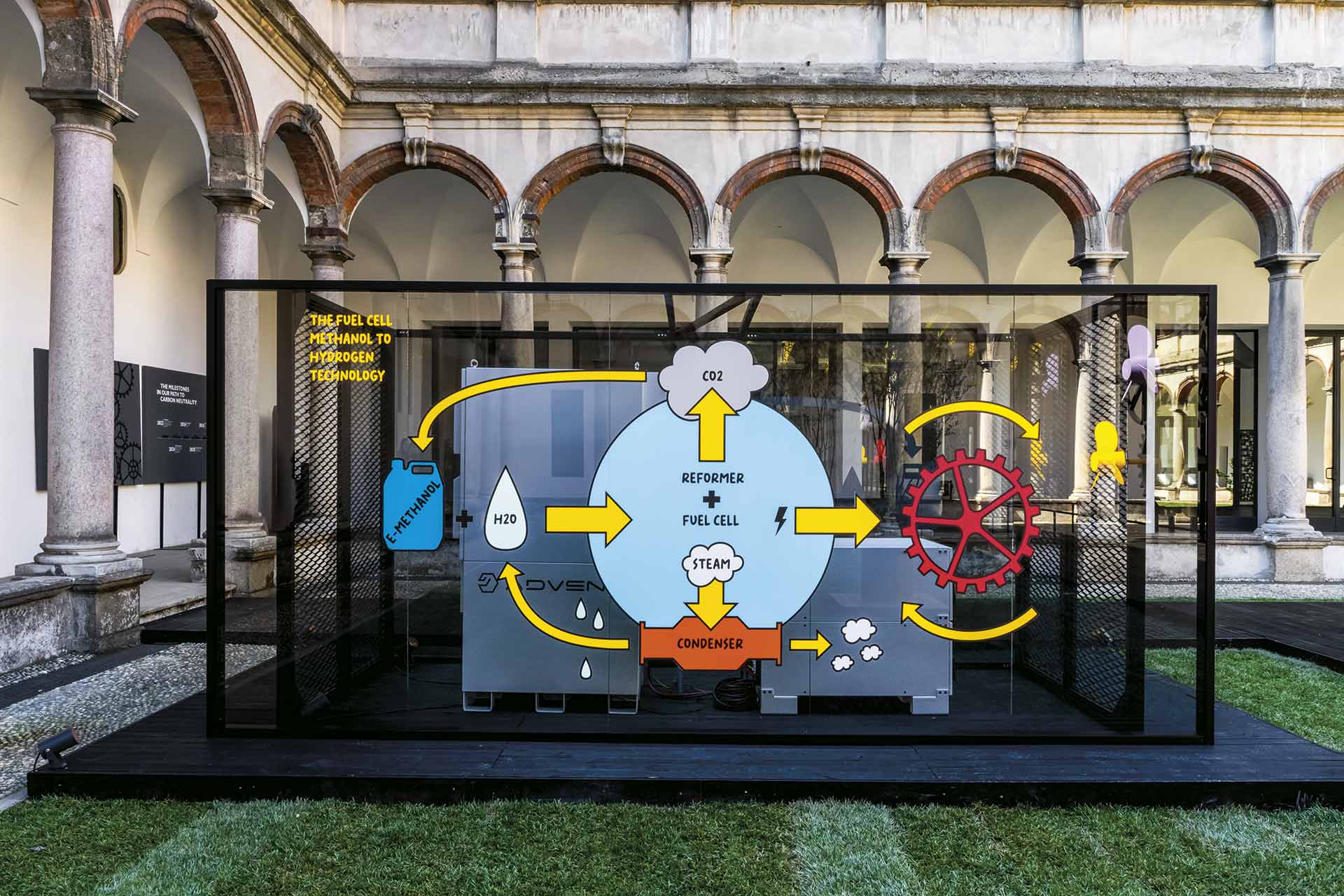

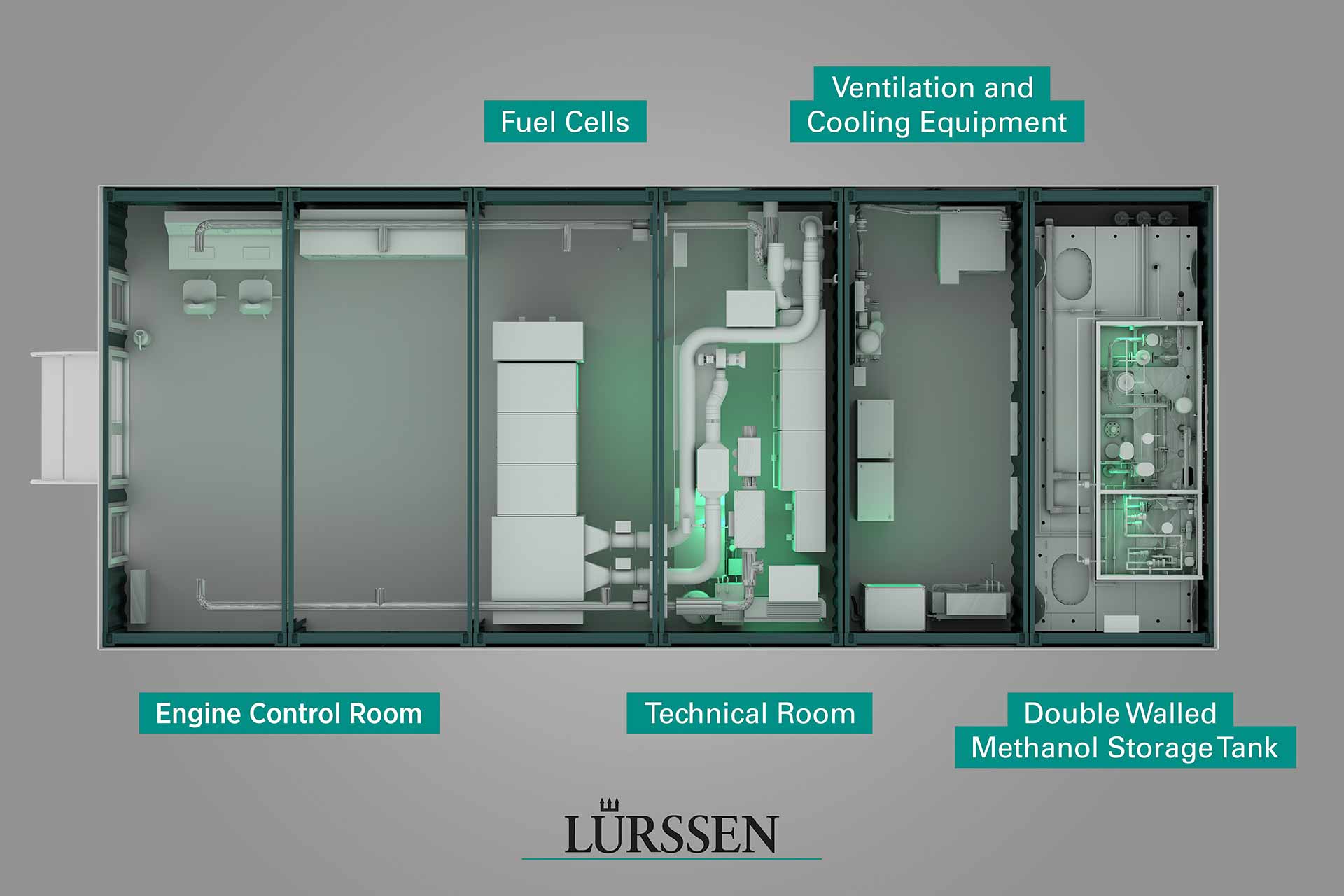

Last year German giant Lürssen switched to sustainable methanol to power their entire plant, while simultaneously developing a yacht powered by synthetic green methanol obtained by sustainable power sources, which should ultimately have zero carbon emissions. Among smaller yacht builders focusing on similar power sources, Sanlorenzo are leading with a 50-meter model already in production, although the industry is still working out methanol storing regulations.

Another type of fuel with plenty of potential for marine use is hydrogen, creating nothing but steam in terms of emissions, and even more interesting for its ease of production, by electrolysis of water. One of the pioneers in this segment is Japanese engine maker Yanmar, already developing a 300kW hydrogen marine fuel cell, as well as lithium-ion batteries to be used with electric engines.

Finally, designers over at MAN are working on Dual Fuel V12 engine, using either diesel or hydrogen as fuel, possibly speeding up the domination of hydrogen as the best sustainable alternative to fossil fuel.

Text Darko Šupuk

Photos Andrea Martiradonna, Sunreef, Evoy, Yanmar, Rolls-Royce & Lürssen